1. Sorts of 3D printers

3D printers use modern technologies that aid you generate physical points. Amongst all the printers, FDM, which is short for Fused Deposition Modeling, is one of the most prominent. FDM develops a model by home heating and also displacing plastic. These printers are very easy to find.

Apart from this, the Selective Laser Sintering as well as Stereolithography are the two other kinds of 3D printing machines, yet they are a lot a lot more costly.

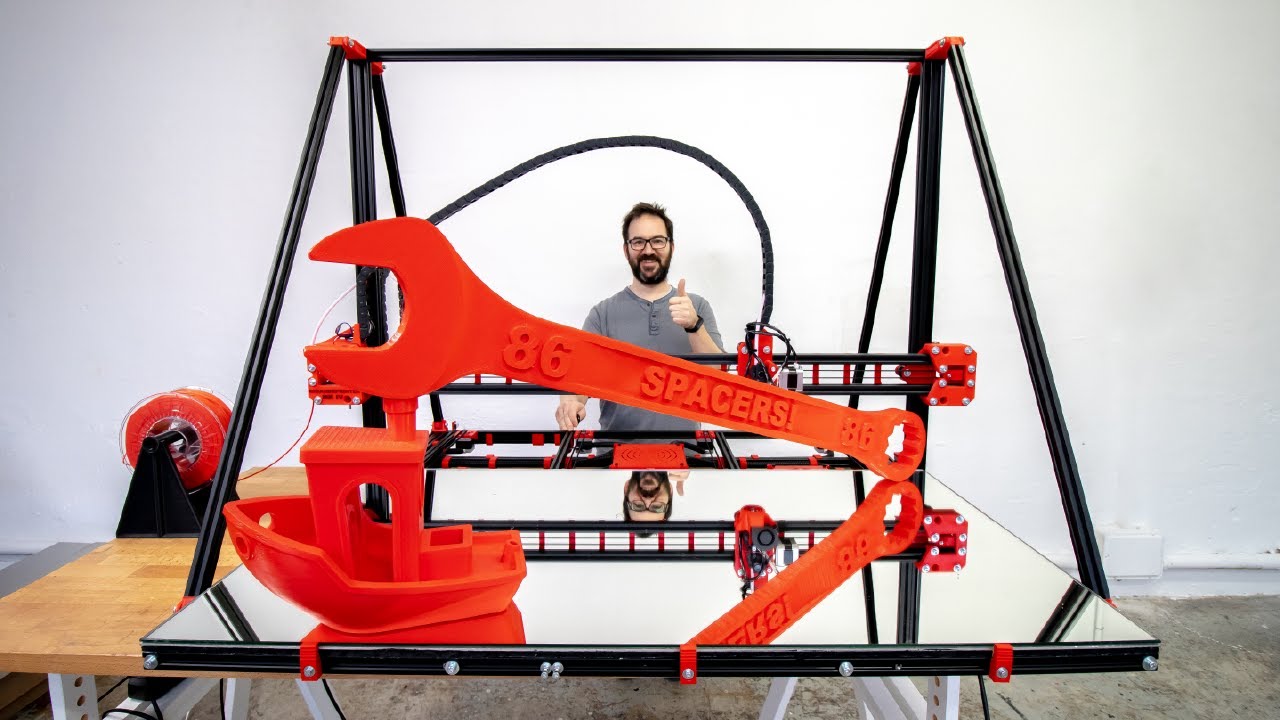

2. Customized Printers

Building your own 3D printer might cost less, specifically if you have a great deal of extra time. Yet if you do not have the time and also skills to construct one, you can choose a pre-assembled printer. If you require one to begin your leisure activity as soon as possible, go ahead and acquire one from the market.

3. Rate

The cost of a 3D printer varies based upon a number of elements, such as the top quality of the outcome. Generally, the high quality printers might set you back as much as $1000. Nonetheless, the specialist devices may set you back greater than $2000. But if you are simply gazing out, we recommend that you choose a basic design that won't cost you more than $100.

4. Products

For printing in 3D, 2 products are called for: Acrylonitrile Butadiene Styrene and Poly Lactic Acid. Both of the materials get soft when warmed, however strengthen when the temperature goes down. The cost of a spool is under $50.

Prior to you pick a product, make certain you recognize what the final product must resemble. Besides this, it is additionally important to note that not all printers will accept both sorts of the product.

5. Security

Security should be your very first priority when it comes to making use of a great 3D printer. 3D printers produce a lot of heat when publishing an item. Make certain you utilize just food-grade plastic for the printer.

6. Top quality

If you want to create high quality published items with your printer, make sure you take into account 2 things: print rate and also resolution. Really, print resolution is the degree of detail the machine can create. Usually, it is in microns. The smaller the microns are the greater the resolution of the item will be. The print speed of the maker determines the rate of the extruder. However, the rate of the equipment will be influenced by numerous elements.

These are a couple of vital points that you should keep in mind when buying an excellent quality 3D printer. Make sure you invest a couple of additional bucks and go with a printer that will publish quality items.

Fast prototyping, likewise referred to as 3D printing, is an approach of making where 3D compounds are rapidly made on a practical dimension of machine linked to a computer having plans for the thing. The fundamental concepts are similar to 2D printer-materials cartridges, flexibility of result, and makeover of code to an evident pattern. 3D printing connoisseurs anticipate that residence fabbers will certainly assist in the personalized industrialized revolution, and substantially lessen the necessity for centralized automation.

The equipment of 3D printers came out in the middle of 1990's. After their introduction, futurists instantly forecasted that the tools would quickly be located in every home. The expense of the parts, which includes numerous flexible, mechanical devices, amounted to over twenty thousand dollars.

Recent 3D printer or copier is a fancy machine utilized by professional designer or product developer, who utilizes it to create versions to be made use of in the presentation to consumers, for example. Nowadays, the present 3D printers utilize different feed stocks like sawdust as well as glue, which may be pressed right into the 3D substance in the duration that the design permits the layers to be incrementally used.

One of the most recent 3D printing devices take advantage of metal dirt as well as a laser in making 3D materials from steel, which make the modern technology additional enticing. These gadgets have been utilized currently by Israel as well as the U. S. in the manufacture of unmanned aerial automobiles or UAVs. The armed force of the United States is researching the battlefield-ready 3D printer which can be used to produce communication devices since they are needed.

Early protrusion of 3D printers considered that they would likely use the combination of unique polymers as well as lasers in the manufacture of items. There are certain polymers that solidify only in specific mix of light. This residential property may be bastardized by utilizing a set of lasers which independently fall short to achieve the optical conditions, however, in concurrence do execute them.

When a set of lasers goes across right into the remedy, it sets. By developing a structure beginning with the dirt up, a steady product might be generated when the solution polymer is sapped away. This process of 3D printing had turned out, more costly and also less precisely demanding method is utilized today.

Later on, we could have 3D printers which will certainly utilize nanotechnology that can make items via dropping them piece by piece. Initial work of the atomic anycubic ebay coupon tooltips will certainly suggest the clinical expediency and also the basic device will certainly create the atomic range like transistors, smaller sized wheels, and also the "strolling DNA". These points can be the leaders to the advanced and more established production systems.